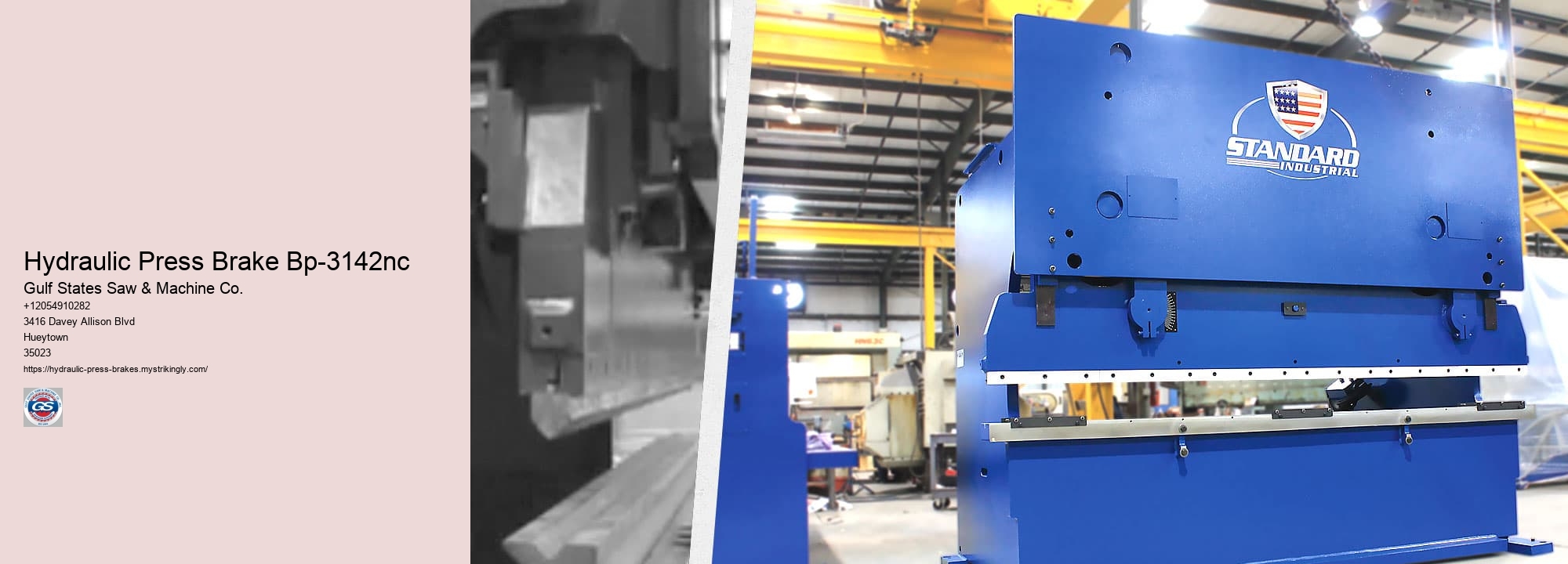

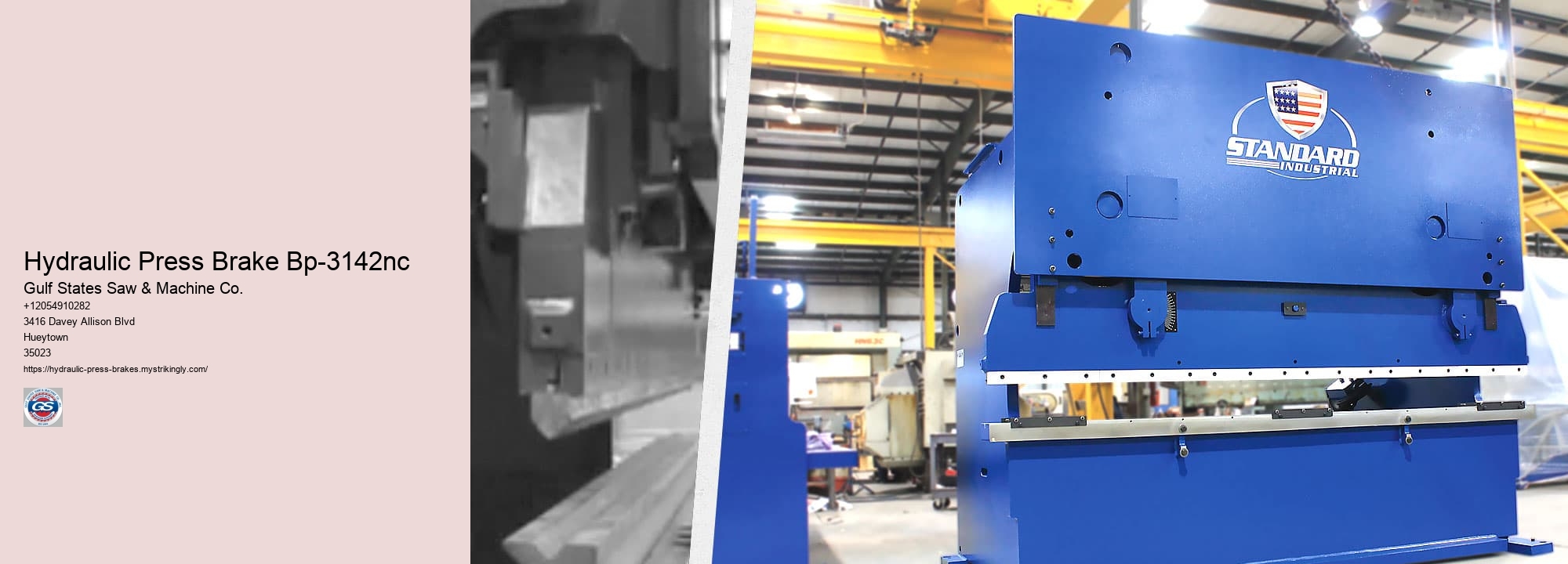

At Gulf States Saw & Machine Co.

In addition to our extensive range of hydraulic press brakes, we offer an assortment of accessories and attachments designed to elevate machine functionality. From hydraulic press brake dies to meticulously crafted tooling kits, we provide all the essentials to bolster productivity and streamline workflow operations.

Whether you're on the lookout for a new hydraulic press brake or require maintenance and repair services for existing machinery, Gulf States Saw & Machine Co. is your trusted ally.

Gulf States Saw & Machine Co. prides itself on offering a diverse selection of hydraulic press brakes tailored to various industrial applications. Whether you're in search of a brand-new machine or a reliable used option, our inventory has something to suit your production needs perfectly. From CNC hydraulic press brakes to manual models, we offer a comprehensive range to accommodate different budgets and requirements.

Maintaining hydraulic press brakes is essential for ensuring their efficiency and longevity. Our team of experts is equipped to provide guidance on proper maintenance practices, including regular inspections, lubrication routines, and prompt repairs when necessary. Controls With our hydraulic press brake troubleshooting services, we aim to swiftly diagnose and resolve any issues that may arise, minimizing disruptions to your operations.

"How does a hydraulic press brake work?"

At Gulf States Saw & Machine Co., we prioritize accuracy and reliability in our hydraulic press brakes. That's why we partner with reputable brands like Nokia Brakes to offer high-quality machines known for their precision and efficiency. With our hydraulic press brakes, you can expect consistent results and enhanced productivity in your operations.

In addition to our extensive selection of hydraulic press brakes, we provide a range of accessories and attachments designed to optimize machine functionality. Whether you need hydraulic press brake dies or tooling kits, we have the equipment necessary to streamline your workflow and maximize efficiency.

Whether you're in need of a new hydraulic press brake or seeking maintenance and repair services for your existing machine, Gulf States Saw & Machine Co. is your go-to destination. Our team is committed to delivering tailored solutions that meet your production goals and exceed your expectations.

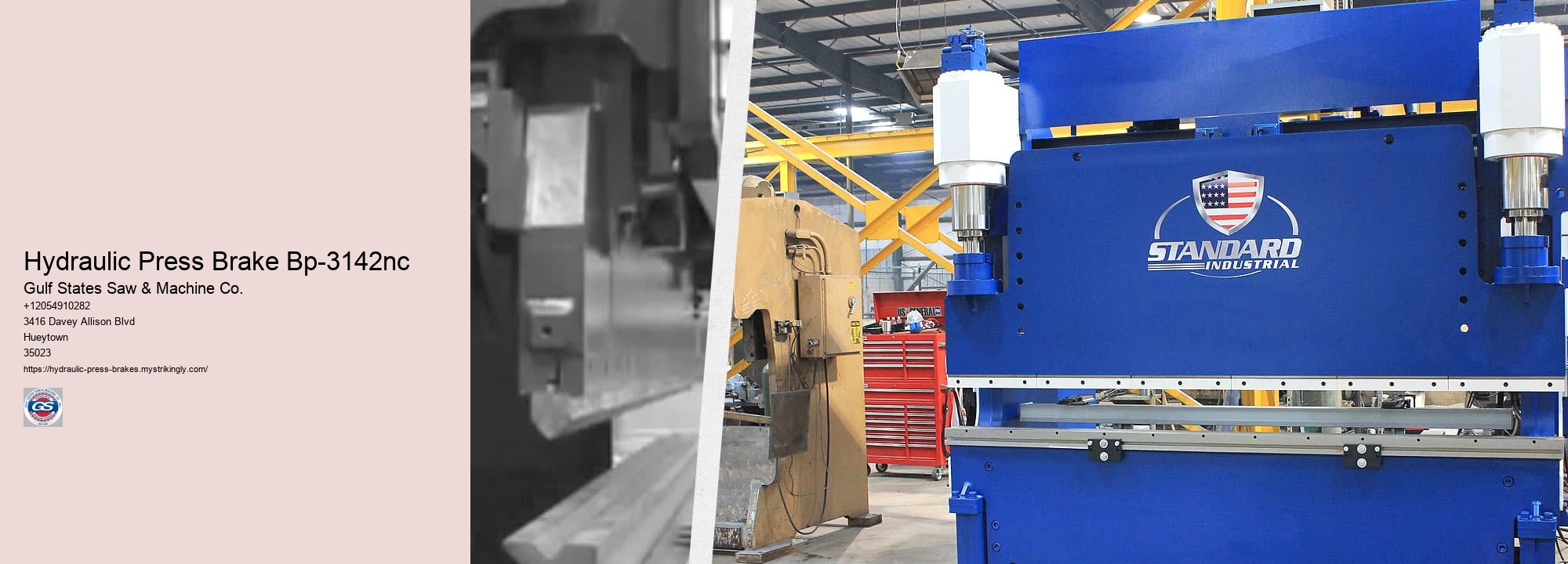

Gulf States Saw & Machine Co.

Maintenance plays a crucial role in ensuring the optimal performance and longevity of hydraulic press brakes. Our team of skilled technicians offers comprehensive maintenance services, including regular inspections, lubrication procedures, and timely repairs. We are dedicated to keeping your hydraulic press brake operating at peak efficiency, minimizing downtime and maximizing productivity.

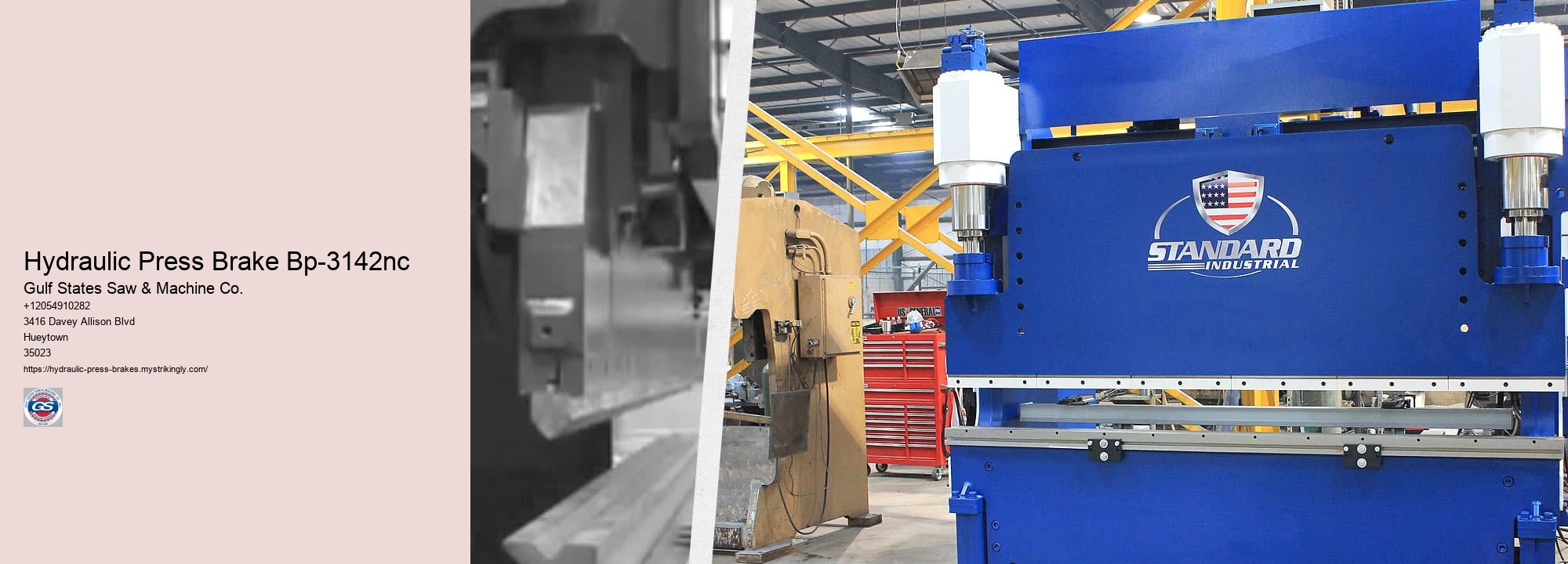

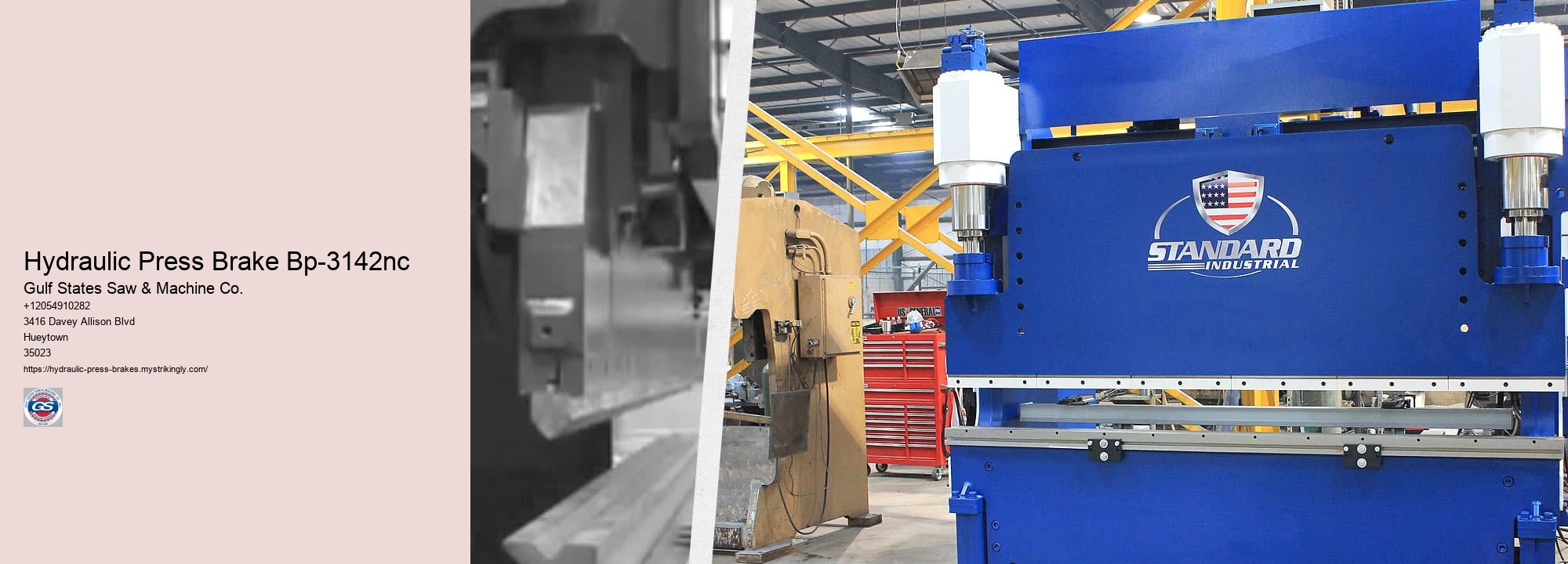

The question "How does a hydraulic press brake work?" is one that many of our clients ask. Hydraulic press brakes operate by utilizing hydraulic pressure to exert force on a punch, which then bends sheet metal against a die. Precision This precise bending process allows for accurate fabrication of metal components, making hydraulic press brakes indispensable tools across various industries.

At Gulf States Saw & Machine Co., we prioritize precision and reliability in our hydraulic press brakes. That's why we partner with reputable brands like Nokia Brakes to offer high-quality machines known for their exceptional performance. With our hydraulic press brakes, you can expect consistent results and enhanced productivity in your manufacturing processes.

In addition to our wide range of hydraulic press brakes, we provide a variety of accessories and attachments designed to enhance machine capabilities. Whether you require hydraulic press brake dies or specialized tooling kits, we have the equipment necessary to optimize your workflow and streamline operations.

Whether you're in the market for a new hydraulic press brake or seeking maintenance and repair services for your existing machine, Gulf States Saw & Machine Co. has you covered.

Gulf States Saw & Machine Co. is your ultimate destination for all your hydraulic press brake needs. Brakes With a vast selection of new and used hydraulic press brakes for sale, we cater to businesses of all sizes and budgets. Whether you're in the market for a CNC hydraulic press brake or a manual model, we have the perfect solution to meet your specific requirements.

Maintenance is essential to ensure the optimal performance and longevity of hydraulic press brakes, and our team of skilled technicians is here to help. We offer comprehensive maintenance services, including regular inspections, lubrication, and timely repairs, to keep your hydraulic press brake operating smoothly and efficiently.

The question "How does a hydraulic press brake work?" Fabrication is one that our team is frequently asked. Hydraulic press brakes operate by using hydraulic pressure to exert force on a punch, which then bends sheet metal against a die. This precise bending process allows for accurate fabrication of metal components, making hydraulic press brakes essential tools in various industries.

At Gulf States Saw & Machine Co., we prioritize accuracy and reliability in our hydraulic press brakes. Power That's why we partner with reputable brands like Nokia Brakes to offer high-quality machines known for their exceptional performance. With our hydraulic press brakes, you can expect consistent results and increased productivity in your manufacturing processes.

In addition to our extensive selection of hydraulic press

brakes, we also provide a range of accessories and attachments to enhance machine capabilities. Whether you need hydraulic press brake dies or specialized tooling kits, we have the equipment necessary to optimize your workflow and streamline operations.

Factors affecting bending accuracy include material thickness, tooling condition, and machine calibration.

Safety measures when operating a hydraulic press brake include wearing appropriate personal protective equipment and following proper operating procedures.

Yes, hydraulic press brakes can perform both bending and forming operations, making them versatile machines.

Yes, hydraulic press brakes can handle a wide range of material thicknesses, from thin gauge to thick plate.